Bio-based carbon fiber may be the future of cycling

It has been a disruptive material, which in the last 20 years has forever changed the bicycle industry. It has made them lighter, stiffer and more aerodynamic, and has brought new shapes previously unimaginable. However, it is also incredibly dirty and difficult to recycle. In these environmentally conscious times, a new revolution is needed, and it may be underway: bio-based carbon fiber may be the future of cycling. Several companies are already working on making it a viable option. Want to know what this innovation looks like? We'll tell you about it.

Bio-based carbon fiber: trading oil for trees

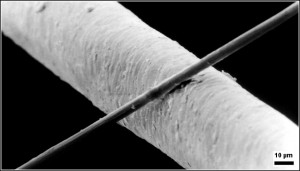

The carbon fiber we are all familiar with is made from polyacrylonitrile, a substance that itself comes from petroleum. This is heated to very high temperatures in the absence of oxygen, so that all non-carbon atoms are extracted. This produces very fine filaments of between 5 and 10 microns (one tenth the thickness of a human hair), which are five times stronger than steel and twice as stiff.

But that's not all: they must then be joined together by means of a polymer (a plastic, after all) that acts as a glue, and which must also be subjected to extreme pressures and temperatures in order to acquire its properties. As you can see, all this involves not only the use of fossil fuels as raw materials, but also huge amounts of electricity and a very complex and costly process; which, by the way, explains the high prices of these bikes, and the fact that it is still a minority sector: world production is barely 150,000 tons per year, compared to some 1.8 billion tons of steel.

RECOMENDADO

Tips for cycling in the rain

25 cycling gifts ideas to get it right

When do helmets have to be changed? Do they have an expiration date?

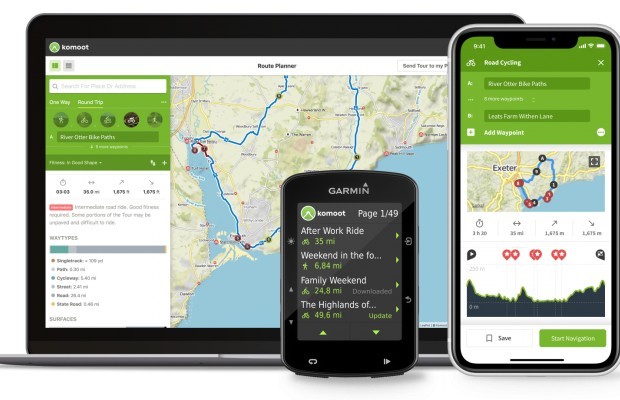

The best apps for cycling and mountain biking

Black Friday 2025 cycling bargains: save on Garmin, POC, Maxxis and more

Black Friday Garmin 2025: the ultimate guide to choosing your GPS at the best price

But back to the ecological impact, last year, Trek presented its first Sustainability Report, which stated that a carbon bicycle has three times the CO2 emissions of an aluminum bicycle. And the aluminum industry is already an electro-intensive industry, which is not exactly clean. Faced with this situation, several companies and institutions are looking for 'greener' alternatives to reduce emissions, as not only bicycles have become 'addicted' to carbon in recent years. Cars, airplanes, helicopters or windmills already use parts of this material, and it is even being tested in construction.

And the focus is on what is called biological carbon fiber, i.e., that which comes from plants, rather than being derived from petroleum. One of the most advanced possibilities lies in lignin, which is one of the compounds that give tree trunks their strength. It turns out that, in addition, lignin is a by-product of paper pulp manufacture, so its extraction would be very cheap and sustainable (moreover, one of the companies that is developing these technologies is the Swedish paper mill Stora Enso, with its NeoFiber). Let's say that it is already 'there', but it is not being exploited.

A cleaner carbon fiber... and cheaper?

But that is not the only advantage of 'bio' carbon fiber. It would also make it possible to reduce the emissions required for its processing by 20% to 30%, according to the German Institute for Textile and Fiber Research in Denkendorf (near Stuttgart), which is one of those involved in this new revolution. That means it would still be twice as 'dirty' as aluminum, but the progress would be huge.

It could even bring down the final price of the material; and the current rise in oil and energy prices only reinforces this idea. Another technology that aspires to achieve this is graphitic carbon.

Finally, we have to consider the taxes and penalties that many governments are already preparing for the industries that generate the most emissions. This could prompt many to look for alternatives in the coming years. Without going any further, another company that is researching is the multinational chemical company Solvay, which announced an agreement with the specialized company Trillium to start producing carbon fiber from acrylonitrile, which also comes from plants. Incidentally, as an unexpected consequence, this could encourage many to follow in Bianchi's footsteps, and bring manufacturing back to Europe, ending the Asian quasi-monopoly.

However, all that glitters is not gold. According to the German institute mentioned above, the biological carbon that has so far been manufactured is of lower quality than that derived from petroleum. So it is not yet ready for use in bicycles, but would be used in medium to low-spectrum applications. For example, Stora Enso (together with its partner, Cordenka) intends to use theirs in the wind industry, which accounts for 20% of the carbon market.

The problem with carbon fiber recycling

On top of all this, the end-of-life of bicycles and other carbon parts is a big puzzle. As with many other plastic materials, it is virtually impossible to recycle it (unlike metals such as steel or aluminum, which are simply melted down and ready for reuse). There are some innovative methods, but they are still extremely expensive, and in addition, the fibers eventually degrade after a few cycles.

Since they often can't be burned either, most of our frames end up buried in old mines that are now abandoned, as experts point out; something you probably didn't know about. It's not clear that the new 'bio' fibers can do anything to solve this problem, but it would certainly be interesting if we could at least start to lower the carbon footprint of ditto bikes.