Tips for safely mounting tubeless tires on hookless wheels

The words of Adam Hansen criticizing the hookless wheel system after the incident suffered by Thomas de Gendt in the UAE Tour have generated a wave of distrust among road cyclists who use hookless wheels. A reliable system that brands have thoroughly tested before launching it on the market, but it requires taking certain aspects into account for safe use.

Precautions to consider when using hookless wheels

The incorporation of hookless rim wheels in road cycling has been a breath of fresh air in the evolution of wheels, an evolution that seemed stagnant from the point of view that a few years ago, it was easy to find competition wheels for tubular tires that combined lightness, aerodynamics, and great rigidity without too many problems.

However, the brands' commitment to the tubeless system has been relegating traditional tubular tires, with the problem that carbon wheels built to hold a tire have a very complex construction in terms of the arrangement of carbon fibers and the materials and resins used, which caused the average weight of the wheels to increase in recent years.

RECOMENDADO

What happens if you exceed your maximum heart rate? Risks of pushing yourself to the limit

How to wash your bike at a gas station without ruining it

Tips for staying motivated to go out riding when cold, rain or night lurk

Can I go cycling with the flu or a cold?

He invented the idea of jumping over the planks, which earned him a World Championship against Van der Poel

How to change the pedals of any bike in 5 steps

Although brands have been hitting the mark to achieve lighter tubeless wheels thanks to the evolution of the quality of available carbon fiber and resins used, the use of hookless rims, that is, without the typical hooks that hold the tire in place, leaving this task in the hands of the air pressure exerted on the tire by crushing it against the rim, has simplified the manufacturing and lamination of the rims so that manufacturers no longer have to reinforce the area as much and therefore can have lightweight, resistant, and cheaper rims.

However, hookless rims have encountered some teething problems, starting with the eternal problems of tolerances in measurements between tire manufacturers and rims, more critical in hookless rims as they lack hooks to hold the rubber in place.

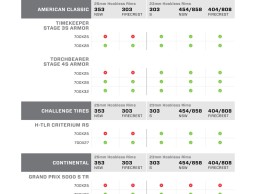

When choosing a tire for our hookless rims, the first thing is to choose a model that guarantees full compatibility with our rim. For this, manufacturers of this type of wheels usually have a list of tires with which they have tested the operation and with which they guarantee full compatibility. It may be annoying to have to stick to certain tire models, but in this case, safety on the bike is at stake.

Within compatibility, it is essential to consider the chosen tire size. Hookless rims usually have an internal rim width of no less than 23 mm, which means that the minimum tire size we can mount is 700x28c, that is non-negotiable. 25mm tires do not open enough to reliably support the walls of the rim.

Another essential parameter when using hookless rims is pressure. If with larger volume and tubeless tires, inflating to 8 bar is a thing of the past, with hookless rims, the limit is even lower, typically set at 5 bar. It may seem like very little pressure, but you have to consider that we are going to use a 28 tire whose inflation pressure is already lower than that of a 25 tire. Besides, we must dispel the traditional idea that higher pressure makes us roll better since for some time now, numerous studies have shown the opposite. Wide tire and the right pressure will give us a perfect balance between cushioning, rolling quality, and grip, both in traction and in curves.

When mounting the tire, the procedure is similar to that of a conventional tubeless wheel. Before proceeding with the assembly, we will verify that the airtight rim tape is well stuck and without wrinkles since, over time and use, or due to incorrect installation, it may not be in a condition to retain air and be a headache.

To mount the tire, we will try to do it preferably without using tools, first inserting one flank with our hands, which we will place in the central channel of the rim, deeper, giving us room to insert the second flank, which we will also place in the central channel. In any case, if we are forced to use tire levers, there will be no problem as there is no inner tube to puncture. The purpose of this is to generate a kind of initial seal to allow air to reach the entire circumference and push the flanks to their final position simultaneously around the circumference.

If the tire is new, we may be able to do the initial inflation using a conventional floor pump. It always helps when seating the tire, to remove the valve core to allow more airflow. In any case, with hookless tires, this initial inflation is a bit more complicated, so having a compressor will always make things easier. Another way to make this process easier is to spray the sidewalls with soapy water.

It is advisable not to introduce the sealant yet and seat the tire without it. This guarantees that the tape, the valve, and the seating of the sidewalls against the rim wall are correct. In this first inflation, we will bring the pressure close to the maximum allowed to ensure that the tire is perfectly seated and we will check that it is seated evenly around the circumference by looking at the seating line that all tubeless tires include on their sidewall.

Finally, we will introduce the sealant with a syringe through the valve before proceeding to inflate to the operating pressure, moving the wheel in all directions to ensure that it seals every corner. For a better seal, it is even recommended to go out for a ride immediately with the bike, it doesn't take much, a few kilometers are enough for the liquid to spread perfectly throughout the wheel.

Another important point to consider with hookless rims is the use of a tube if we have a puncture that the sealant cannot seal. A tube can be used but only occasionally to complete the route and maintaining the pressures we would use with tubeless, which inevitably poses a risk of puncture due to hitting the rim. However, we should not use a tube continuously as its use usually causes the tire to not seat correctly, which could cause the tire to come off, meaning hookless and tubeless are inseparable.