Specialized extends its Mirror technology with the addition of the new Romin EVO Pro

If in one area of cycling, 3D printing technology has fit perfectly and has made it possible to create much better products, it is in saddles. A technology that, as in other products, Specialized has managed to bring to excellence. Now, it is extending it across its range to make it available to many more users.

Romin EVO Pro with Mirror, performance and comfort in one saddle

Reducing pressure on the perineal area has been the keystone of saddle manufacturers for years. A quest in which Specialized has always been one step ahead thanks to its Body Geometry philosophy whereby its products are designed and created, using the available science, to fit the rider's body and not the other way around.

A few years ago, the evolution of saddle manufacturing technologies gave rise to the Mirror saddles, or in other words, the 3D printing construction of the saddle shell, which makes it possible to fine-tune not only the shape of the saddle, but also the way in which the saddle deforms under the weight of the cyclist.

RECOMENDADO

How to change the pedals of any bike in 5 steps

Alcoholic beverages with the fewest calories

What would you do if you won the lottery? This cyclist bought himself a €20,000 bike

Tips for cycling in the rain

25 cycling gifts ideas to get it right

When do helmets have to be changed? Do they have an expiration date?

A technology that Specialized is now extending across its range with the addition of the Romin EVO Pro saddle with Mirror that uses the same 3D printed pad as the bigger version, the S-Works Romin EVO.

The Romin, unlike the famous Power, is a traditional saddle with an elongated cut for those who do not feel comfortable only with the support on the ischiums as is required by the increasingly common saddles with a shortened tip, such as the Power.

In this new Romin EVO Pro, Specialized uses nylon and recycled carbon fibre in the construction of the frame while the rails are made of titanium instead of carbon as in the S-Works version.

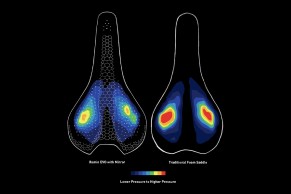

The 3D Mirror matrix used by the Romin is available in 155 and 143 mm widths and features 22,200 nodes and 10,700 struts as well as a specific concave design that Specialized claims reduces pressure by up to 26% compared to traditional saddles.

To achieve this precise shape, Specialized has worked hard to detect common problems that affect riders in the saddle area and, through the use of pressure mapping, measure blood flow in the perineal area. In addition, Specialized has the great advantage of having a wealth of positioning data from the Retül system that allows them to give context to both the problems riders are experiencing and how to solve them.

With all this in the shaker Specialized has not only created a saddle that reproduces the great comfort of the S-Works version but at a more affordable price but, thanks to the use of recycled carbon, reduces waste emissions and all this creating a reasonably light model, 243 g in the 143 mm wide version and that you can already find in its catalogue with a price of 370 €, 100 less than the S-Works version.