Prologo NAGO R4 PAS 3DMSS: "The lightest 3D saddle on the market"

After years of relying on its top-of-the-line saddles with CPC absorption technology, the Italian brand Prologo joins the trend of 3D manufacturing to create an ultralight saddle, the new Nago R4 PAS 3DMSS, elaborately crafted with different three-dimensional structures depending on the area of the saddle.

Prologo leverages 3D printing technology to create its new Nago R4 PAS 3DMSS saddle

Based on pressure studies carried out with their Pressure Map MyOwn technology, which analyzes the pressure exerted by the cyclist on each part of the saddle and which Prologo has been using for a few years to recommend the ideal saddle to each cyclist within their wide range, the Italian brand has used this data to create their first saddle made through 3D printing, a technology that, when applied to saddles, is yielding excellent results as affirmed by all those who have used a saddle manufactured using this methodology.

For this first saddle manufactured through 3D printing, Prologo has chosen the dimensions and design of their Nago model, undoubtedly the best-selling model from the Italians and one that adapts to a wide range of physiques with its semi-curved shape. In this new model, Prologo has not limited itself to replicating the shapes of their current saddle with 3D printing, but has created what they have called 3DMSS, initials in English for 3D Multisectorial System which alone defines how the brand approaches the manufacturing of this saddle.

RECOMENDADO

Tips for staying motivated to go out riding when cold, rain or night lurk

Can I go cycling with the flu or a cold?

He invented the idea of jumping over the planks, which earned him a World Championship against Van der Poel

How to change the pedals of any bike in 5 steps

Is it possible to do base training when time is short?

Alcoholic beverages with the fewest calories

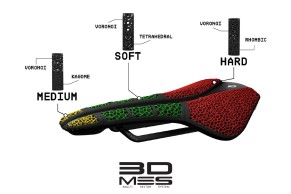

The shell has different sectors distinguishing between the tip of the saddle, the middle part, and the support area for the ischial bones. Different printing patterns are used to vary the flexibility of each area, with the rear part where the support is located being the firmest, the central part being the softest to allow for better shock absorption in this delicate area, and a tip with intermediate flexibility to allow support in that area when pushing hard but not be uncomfortable when receiving impacts while seated in this area.

Furthermore, Prologo has focused on trying to avoid the Achilles' heel of 3D printed saddles: a higher weight than their conventional counterparts. Thanks to the MyOwn studies, Prologo was able to determine the areas where the cyclist exerts more pressure and could remove material from the less demanded parts.

Additionally, the entire 3D structure is supported by a thin layer of carbon fiber and the construction is finished with their usual Nack carbon rails, kevlar, and aluminum filaments with which the brand has been manufacturing extremely lightweight and robust saddles for years. The result is a saddle weighing only 149 g, the lightest of all saddles currently using 3D printing technology.

This new NAGO R4 PAS 3DMSS will be available in stores in early April, initially in a single size of 245x137 mm and with a price in line with other models manufactured in this way, which is 420 euros.