Mini-hook tires: why they are coming to the WorldTour and what it means for the cyclist

After the controversies that arose over the last year regarding the use of hookless rims, brands have found a middle ground with the construction of mini hook rims that combine safety when securing the tire of the traditional tubeless section with the lightness and ease of manufacturing of hookless rims.

Manufacturers Find Balance in the Mini Hook Design of Their Rims

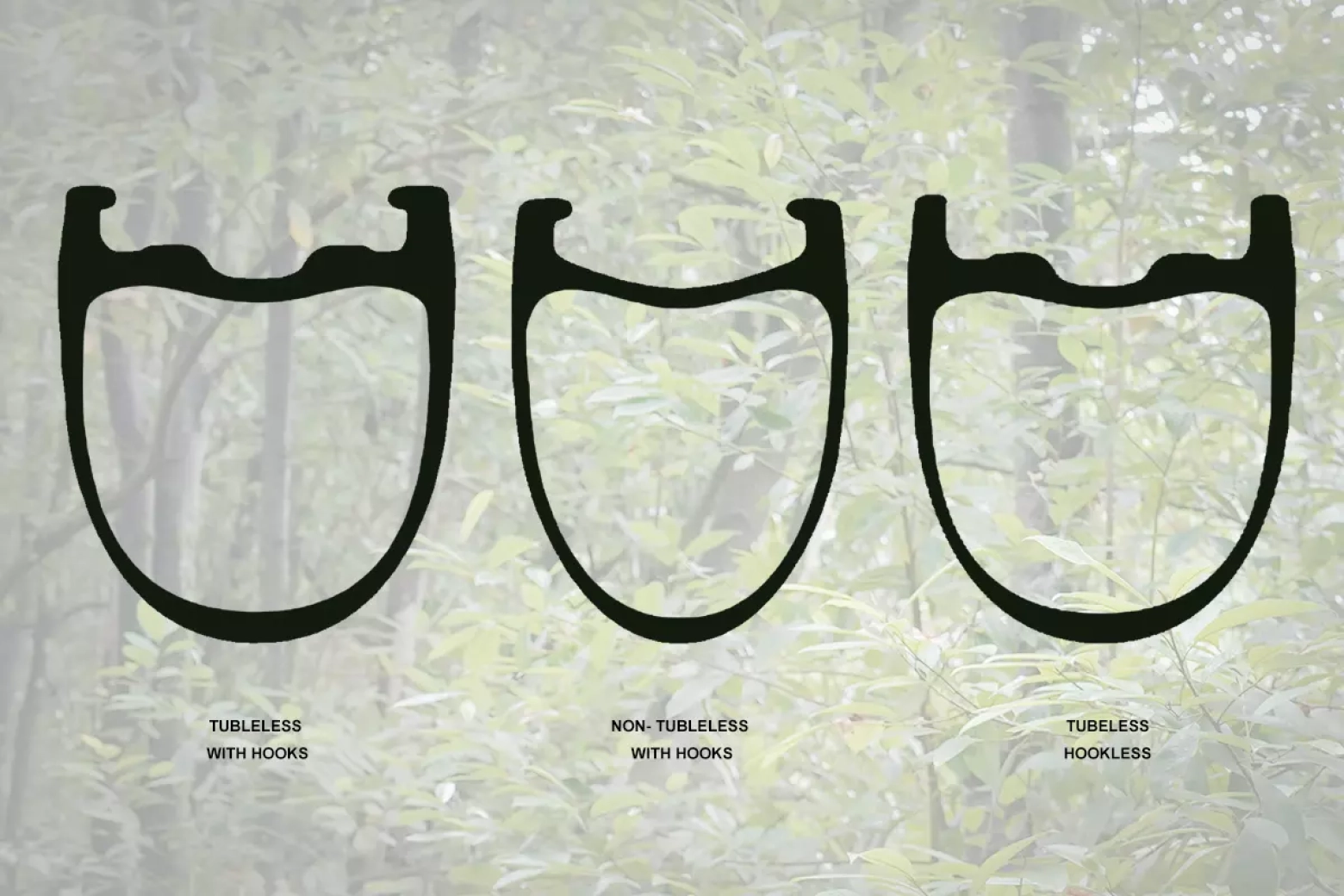

In recent years, the arrival of hookless rims in road cycling seemed to be the answer to the average weight increase of wheels that had resulted from wider rim widths and, above all, the abandonment of tubular rims in favor of tubeless. A hookless system that seemed to offer only advantages in terms of lower weight, better rim/tire integration to enhance aerodynamics, and cheaper manufacturing.

However, some unexplained tire blowouts like the one suffered by Thomas de Gendt put the hookless system under scrutiny, with the UCI conducting an investigation and harsh criticism of this type of rim from some industry figures like the CEO of Silca, who had previously been part of Zipp.

RECOMENDADO

Can I go cycling with the flu or a cold?

He invented the idea of jumping over the planks, which earned him a World Championship against Van der Poel

History of the Specialized Tarmac: eight generations of records, evolution, and an unbeatable legacy

30-minute roller sessions to improve

How to change the pedals of any bike in 5 steps

Is it possible to do base training when time is short?

In light of all these issues, wheel brands have sought a solution that allows them to avoid the main drawbacks of the hookless system in road cycling, such as the need for tighter tolerances between rim and tire, which means that not all tire models are compatible with a specific hookless rim model.

One of the first to launch their rims using what is now called mini hook were precisely some of the first who bet on hookless in road cycling, such as ENVE, which at the beginning of the year launched their SES 4.5 Pro wheels that have been used by cyclists from UAE Team Emirates-XRG throughout this season.

A mini hook system that, for all intents and purposes, can be considered as hooked rims since the only thing manufacturers do is minimize the specifications set by ETRTO. In the case of ENVE wheels, with hooks of just half a millimeter, which, however, are sufficient to improve tire retention and allow pressures of up to 6.8 bar, significantly more than the 5 bar that hookless rims accept as a maximum.

In this way, the construction of the rims remains simple and economical for manufacturers, without the need for the laborious manufacturing that traditional hooked carbon rims required, where design and production were very critical to ensure sufficient strength. In fact, some manufacturers maintain the same method they used for their hookless rims but eliminate some layers of material on the lower part of the flanks to create the hook, which even allows them to shave off a few more grams from the already lightweight rims.

Mini hook rims, having very small hooks, do not create problems when mounting tires as occurred with the original tubeless design, where, in many cases, it was difficult to get the tire flanks into position, often requiring a compressor for the initial mounting.

Moreover, the fact that mini hook rims are de facto hooked rims means that incompatibilities between rim and tire that affected the hookless system are eliminated. However, this type of rim still has its defenders, mainly from Cadex, the premium component brand of Giant and one of the main proponents of hookless, who claim that the use of the mini hook is nothing more than a marketing operation and that in reality, these reduced hooks do not provide any extra safety for tire retention.