Advantages and disadvantages of hookless wheels

After an introduction to the market with many doubts and the suspicion of users, hookless wheels are being incorporated into the ranges of different manufacturers who find in this new configuration the secret to being able to achieve light and reliable tubeless wheels. However, it is unlikely that they will end the production of wheels with conventional rims as it is a system that presents limitations for certain users.

Hookless wheels begin to dominate the tubeless wheel offer

The tubeless system, developed by Mavic when the French brand created its UST at the beginning of the 21st century and opened the patent so that any brand that wished could use its specifications in search of creating a standard for tubeless wheels, has been popularized over the years.

In mountain biking, it has long been fully installed in users of a certain level due to its unique advantages in avoiding punctures and the much greater traction and grip capacity that is possible thanks to being able to reduce the pressures used, pressures that, with the current wide tires with casings designed for it, reach ridiculous values that, on the other hand, allow the bike to pass much more easily through sections almost inconceivable years ago.

RECOMENDADO

Can I go cycling with the flu or a cold?

How to change the pedals of any bike in 5 steps

Is it possible to do base training when time is short?

Alcoholic beverages with the fewest calories

Cycling tips for the Christmas season

What would you do if you won the lottery? This cyclist bought himself a €20,000 bike

Road cyclists are also discovering tubeless in recent times which, thanks to the push of wheel brands, have managed to practically forget about the tubulars of a lifetime, even in terms of competition. Again, the greater resistance to punctures and the ability to reduce pressures which, in addition to the extra grip achieved, results in an improvement in rolling resistance have made this system to be implemented quite quickly and without hardly any controversy as happened, for example, with disc brakes.

The evolution of tubeless has continued in the search for a lower weight since, for example, compared to old road tubular wheels the difference was notable and on the other hand to achieve a simpler and, therefore, cheaper construction of the wheels. For this, as has happened on other occasions, manufacturers set their sights on how car and motorcycle wheels are designed, which, after all, have been using tubeless tires for decades.

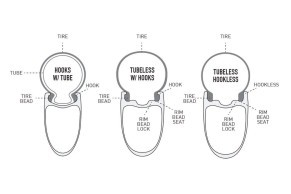

This is how hookless wheels emerge which, as its name indicates, consists of eliminating from the wheel structure the hooks on its sides that have traditionally been responsible for trapping the tire between them and the rim walls. However, if the wheel and tire measurements are correctly designed and adjusted with the tubeless system, these hooks are no longer necessary since the force is exerted on the walls of the sides, especially with the current rim designs that by gaining in width have managed to make the tires receive less load at that point.

The hookless wheel system was first incorporated into mountain bike wheels and later into gravel models, in both disciplines due to the use of very low pressures that made it easier for the tires to stay in place without the need for hooks. However, this same reason of using increasingly wider tires and at less pressure that has also been extended to the road has made hookless wheel models for this discipline also appear.

As we explained, the main problem that hookless wheels present is that, to work correctly, the adjustment between wheel and tire must be very precise. In fact, this has historically been the origin of most problems with tubeless tires. Finally, ETRTO, after many years of manufacturers demanding it, have established a standard that precisely sets the measurements and tolerances that hookless tires and wheels must comply with. In any case, wheel brands continue to carry out their own tests and publish lists of tire models compatible with them.

In any case, the hookless wheel system has the limitation of the maximum pressure it can withstand which, in the case of road wheels, is not higher than 5.5 bar. That is why it is common for the minimum tire size used on hookless road wheels to be 700x28c, on the other hand, a size increasingly common among professionals.

As we pointed out before, dispensing with the rim hooks allows the wheel manufacturer to achieve greater resistance on the sides with less material as it does not have to make the carbon fiber the complicated curve that the hook implies and that becomes a point of tension. This results in lighter wheels without loss of resistance. Apart from that, it also means that the transition between rim and wheel is smoother which, according to manufacturers, improves the behavior of the tire sides when they deform in cornering supports or when they absorb impacts.

And what happens in case of a puncture? Many ask. In principle, most manufacturers indicate that a tube can be put in as an emergency solution, although respecting the maximum pressures of the system which, on the other hand, leaves us more exposed to punctures by having to use a much lower pressure with a tube than we would normally use. That is why the hookless system practically ends the full compatibility of traditional tubeless with the use of tubes, something that can be a disadvantage when we cannot properly repair a tubeless puncture, for example if we suffer a cut in the tire on a multi-day trip.

It is for things like this that it is not foreseeable that hookless tires will end those of conventional design although they offer an excellent option for those cyclists who prioritize above all the performance of their bike.

Advantages of hookless wheels

- Lower weight.

- Better behavior of the tires.

- More robust and easier to manufacture wheels.

Disadvantages of hookless wheels

- Need to pay attention to the compatibility between wheel and tire.

- Reduced maximum pressure limit.

- Impossibility of using with a tube except occasionally to get out of trouble.