The €75,000 bike to beat the hour record

Filippo Ganna managed to break the hour record on a Pinarello bike that has taken 3D printing to the limit. A technology that has allowed them to create unthinkable shapes on a unique bike custom-made for the Italian rider.

Filippo Ganna smashed the hour record on a very special Pinarello Bolide

Filippo Ganna achieved an incredible performance in his assault on the hour record. The best time trialist of today, with the permission of Remco, Wout and company, managed, in the velodrome of the Swiss city of Grenchen, to set the hour record, which was in the hands of Daniel Bigham, performance manager of his team, INEOS Grenadiers, who set it at 55.54 kilometres in the same velodrome this August, in a superhuman 56.792 km that not only beat the existing record but also reached the mythical mark achieved by Chris Boardman in 1996 with a bike later considered illegal.

The data collected during Bigham's attempt was tremendously useful in developing the material used by Filippo Ganna in his attempt, especially for the construction of the Italian's bike, in which Pinarello has used the latest technology in order to create a long-lasting mark.

RECOMENDADO

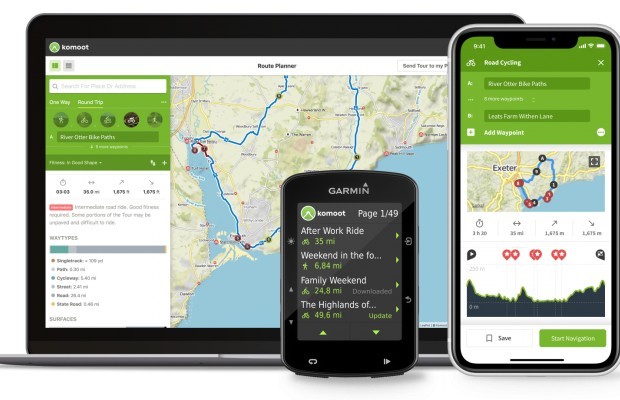

The best apps for cycling and mountain biking

Black Friday Garmin 2025: the ultimate guide to choosing your GPS at the best price

How to wash your cycling clothes? 10 keys to make them always look new

The real importance of signing up for a race

The best road bikes of 2025

The best gravel groupsets of the moment

Completely custom-built for Filippo Ganna, Pinarello has used 3D printing technology to manufacture a very unique version of its Bolide. A technology that has allowed them to bring to the physical bike the aerodynamic innovations they have developed for this model that could hardly be manufactured using the usual techniques.

In particular, the design of the seat tube and seatpost stands out, whose leading edge has a series of protuberances that are intended to better control the flow of air by generating small vortices that create a controlled turbulence that manages to keep the air as close as possible to the tube, thus reducing interference with the rider's legs to a minimum.

Of course, Pinarello is also taking advantage of the relaxation of the UCI rules regarding the proportions between width and depth of the aerodynamic profiles, the famous 3:1 rule. In fact, this Bolide F HR aims to be as narrow as possible, returning to a paradigm that seemed forgotten, not even in the fork, where the tendency is to increase the distance between the legs trying to avoid the interaction between the legs and the air flow that runs through the wheel.

Finally, we cannot forget the characteristic couplers, also made by 3D printing, which Filippo Ganna has been using all season and which, with their peculiar shape, redirect the air to guide it to the desired area so that the movement of the rider's legs generates the least possible resistance.

Cutting-edge technology

Beyond the meticulous aerodynamic design, the most important thing about the Pinarello Bolide F HR is the use of 3D printing technology in a fully functional bike.

3D printing has been used for years by different brands to create prototypes on which to validate in the wind tunnel the different aerodynamic solutions created using fluid dynamics or CFD software.

Ver esta publicación en Instagram

Pinarello wanted to go one step further and thanks to the collaboration with the British company specialised in 3D printing Metron Advanced Alloy they have managed to print a fully usable bike frame.

This Pinarello Bolide F HR is made from an aerospace material called Scalmalloy. It is an alloy of scandium, aluminium and magnesium designed specifically for use in 3D printing.

The printer produces the frame in 5 separate parts that are joined together using epoxy resin, a common procedure in the production of carbon bikes, this time, of course, applied to an aluminium alloy.

To demonstrate the reliability of the construction, a test unit was sent to the EFBE laboratory, which specialises in bicycle testing, where it passed the ISO4210 certification that defines the safety standards for bicycles. A machine that Pinarello intends to make available to its customers, on demand, however, due to the peculiar manufacturing system used.

Pinarello Bolide F HR: record set-up

In equipping this bike, INEOS Grenadiers has left nothing to chance so that Filippo Ganna can count on maximum guarantees in his assault on the hour record.

The most important part of the bike's performance, the wheels, are left in the hands of Priceton, who provide lenticular wheels that are fitted with Continental GP5000 TT tubeless tyres. The crankset is made by WattShop, Daniel Bigman's own aerodynamic components company, with its aerodynamic Cratus model, with a length of 170 mm for Ganna, a rider of 1.93 m in height.

For its part, the chain, supplied by Muc-Off, is an Izumi Kai whose lubrication has been optimised by using ultrasound to reduce friction to a minimum, providing a 15% gain over a conventional one, which in the current Bigham record was a considerable 87 metres extra.

Filippo Ganna chose a 64x14 set-up for this record, which meant that he had to ride at an average cadence of between 95 and 98 pedal strokes per minute to beat Bigham's record. Taking into account the estimated aerodynamics of the Italian, the average power he had to sustain in his attempt has been estimated at around 450 W.

This Pinarello Bolide F HR 3D, has an estimated cost of around €33,000. To this should be added a figure of between €17,000 and €20,000 for the unique titanium handlebars also made by 3D printing. The Princeton wheels are also a specific development to maximise the aerodynamics of the Pinarello Bolide which would add €8,000 to the bill. The low-friction Muc-Off chain is €1,250. Also not to be ignored is the cost of the time trial suit worn by Gana, which was designed exclusively for this attempt and would also cost around €8,000.

- Frame: Pinarello Bolide F HR 3D Scalmalloy 3D printed frame

- Handlebars: 3D printed titanium

- Wheels: Princeton CarbonWorks Track Special

- Tyres: Continental GP5000 TT

- Crankset: WattShop Cratus Aero. 170 mm, 64 tooth chainring

- Gearing: WattShop Cratus, 14 teeth

- Chain: Muc-Off Izumi Kai

- Saddle: Fi’zi:k Ares TT