How to know what is making noise on your bike and how to fix it

Noises on the bike can be one of the most frustrating things for a cyclist, especially for road cyclists where they go unnoticed due to the noise of the tires while pedaling on paths or stones. These noises can sometimes turn into a real headache, even for the most experienced mechanics, when it comes to determining their origin. Here we provide some general guidelines to put a stop to them.

Cyclist CSI, in search of hidden noise

Facing a long route on our bike and having to constantly endure rattling, creaking, or squeaking every time we touch the brake is something that can drive anyone crazy. In fact, if we go to the extreme, it can even become a safety issue to the point that the cyclist is more worried about the noise that tortures them than paying necessary attention to the terrain.

It is true that today's bikes are incredibly reliable machines that, with a little maintenance, can offer us thousands of kilometers of satisfaction. However, like any mechanical element, they are always susceptible to failure, misalignment, or unwanted friction and vibrations.

RECOMENDADO

What are the five monuments of cycling?

The World XCO Champion kicks off the season at the Internacionales de Chelva 2026

How much time would a professional cyclist take out on an amateur in a race?

Shimano partners with the new Canyon × DT Swiss All-Terrain Racing team

Without a team, with used equipment, and still winning: the case of Maximilian Brandl

Pogacar caught with a new time trial bike

Generally, dirt tends to be a great ally of noises. Keeping the bike clean and well-lubricated usually eliminates a large number of them. However, we must also be cautious when washing the bike, as applying excessive pressure with water may end up removing the grease that protects and lubricates the bearings, making the remedy worse than the disease.

These are some of the most common issues in our machines that end up becoming annoying noises.

Clicks

Without a doubt, of all the noises that plague bicycles, the most exasperating. They can be rhythmic and constant, appear only when we pedal, or be sporadic, which often makes it very difficult to find their origin.

The first suspect whenever clicks appear, especially when they are rhythmic, is the area of the bottom bracket, especially if your bike uses a press-fit bottom bracket. When this happens, the first point to check is to remove the cranks and clean the area of any mud, water, or other dirt. Both the cranks and the supports on the bearings. We will check that the bottom bracket bearings spin smoothly without hard spots or scraping, and of course, that they have no play.

After doing this, we will apply grease, preferably Teflon-based to add greater water resistance, and we will reassemble the cranks and secure them to the torque specifications set by the manufacturers. If the problem persists, we will have no choice but to extract the bearings. This is straightforward if our frame uses a BSA threaded bottom bracket and requires specific workshop tools if it is of the press-fit type. In both cases, we will clean the bottom bracket and replace the bearings at any sign of not spinning smoothly. Of course, grease will again be our ally before reassembling the cups.

Another source of rhythmic clicks is something as trivial as the valve of the wheels if you are using tubes. Especially in the case of using carbon wheels with a significant profile and long valves. The small oscillation and the tapping of the valve in the hole can be the source of a noise that is often quite difficult to locate and is solved with something as simple as a small piece of electrical tape stuck to the valve and attached to the rim to prevent its movement.

Staying with the wheels, we have also found metallic clicks originating from the spokes of some of them, whether at their seats in the hub or at the support of the nipples on the rims. A noise that is especially noticeable when standing up. A drop of chain oil in these areas often eliminates these noises, which, in any case, are becoming less common with current wheels that are laced with very high tensions minimizing flexing.

Finally, another classic, the saddle and its rails in contact with the seat post. Often, its origin is a poor seating of the rails in the grooves of the post, which is solved by being meticulous in the placement of the saddle, checking that our post is compatible with the type of rails of the saddle - round or oval - and that the torque applied is within the range specified by the post manufacturer.

Squeaks

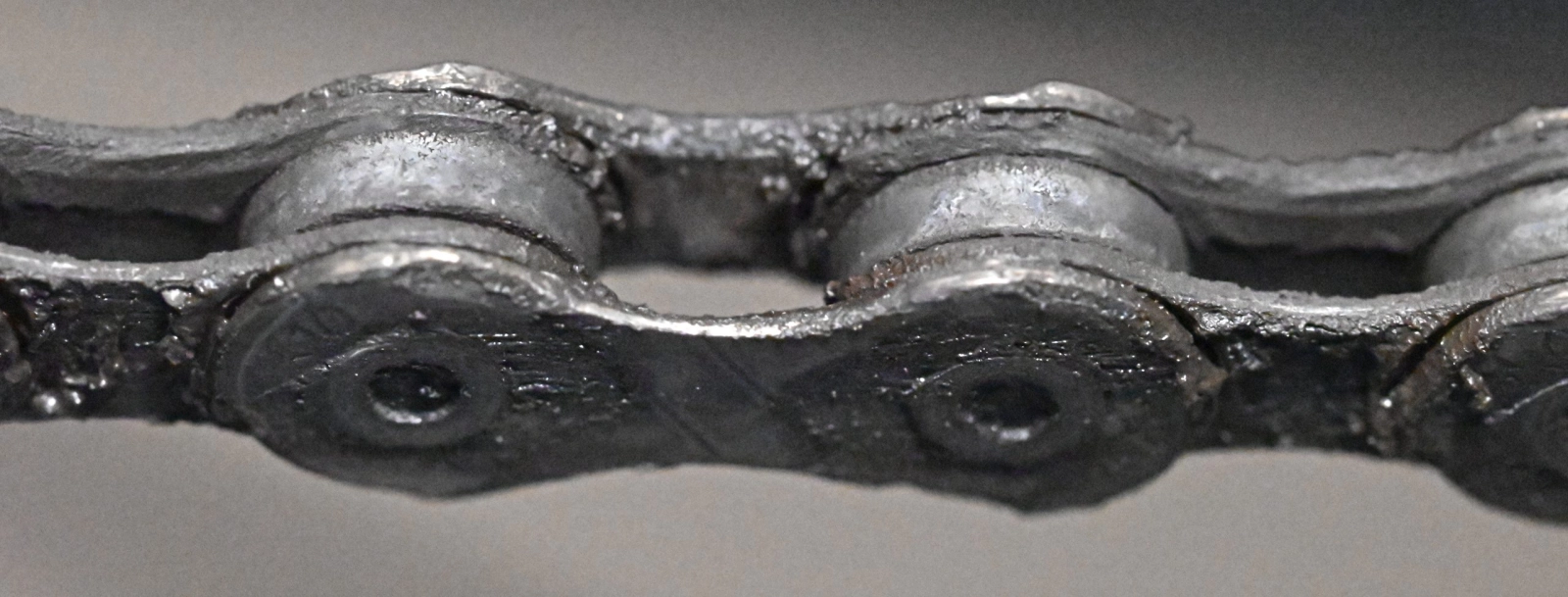

Unlike clicks, their origin is usually easier to determine, although their solution is not always straightforward. The most common ones affect the transmission and are often caused by poor maintenance of it. Remember that a clean transmission will last in perfect working order much longer, and when lubricating the chain, it is better to err on the side of caution than to overdo the oil. A drop of lubricant on the inner side of each link is sufficient. More means that dirt will stick more easily and cause a sludge, a mix of grease and dirt that becomes real sandpaper that shortens the life of the transmission.

It is also advisable, when we see it particularly dirty, to disassemble the chain, cassette, and if you have electronic shifting, which is a simple task, also the derailleur to place them in a container with degreaser and, with a little patience and an old toothbrush, leave them completely spotless.

Disc brakes are another common source of squeaks beyond the rubbing that usually occurs due to poor adjustment. If the problem is this last one, the first thing we will do to eliminate the noise is the classic method of loosening the caliper, squeezing the brake so that it goes into place, and then tightening the screws again. However, many times this method does not work because the pistons do not press the disc evenly.

Solving this is a bit more complex and involves removing the pads, pushing the pistons out a bit, being careful not to let them come out of their housing, and, with a small cotton swab, cleaning the sides of the pistons and lubricating them with the system's own fluid: DOT or mineral oil. Then, with a plastic tool that does not damage them (a tire lever is ideal), we return them to their housing, repeating the operation several times until the pistons come out evenly.

Sometimes, however, squeaks in the brakes are somewhat inevitable. Often caused by the small vibration of the pads in their housing, which do not always fit perfectly, especially if we use non-original lower-quality alternatives. Replacing the pads often resolves the issue. In any case, depending on the compound of the pads, it should be noted that in the rain, practically all discs squeal to a greater or lesser extent.

Without being squeals, the wheel bearings can also be the source of a constant hum as they deteriorate with use. Since most wheels on the market today use sealed bearings, maintenance involves opening the hub and checking that the spin is smooth and without play. If any of this occurs, do not hesitate to replace them, preferably with quality ones that guarantee more time without problems.

The same can be said for the steering or the pivots on mountain bikes. Anywhere there is a bearing, it is essential to keep them clean, lubricated with grease to reduce the possibility of water ingress, and properly tightened to their correct point, replacing them when their spin is not smooth or play appears.

Creaks

We leave for last the most dangerous and concerning, and that is, when we hear dry creaks, we must consider that one of our carbon parts may be about to fail. Here, the checks involve meticulously reviewing, looking closely with a flashlight, the frame, seat post, handlebars, wheels, etc., to try to find any visible cracks. We will also press, without fear, along the surface of those parts to try to reproduce the noise and, in the case of the handlebars, we will twist it deliberately with the bike on the ground. If the noise is reproduced, we must immediately stop using that component.

The common points of appearance of problems in carbon are the tightening of the levers on the handlebars, the fixation of the stem on the seat tube, the horizontal tube in the area of the handlebars' rotation that can hit in a fall, the union of the chainstays with the bottom bracket, and the interior of the seat tube in the area where the wedge of the seat post exerts force.

To avoid suffering problems of this type, when dealing with carbon parts, it is mandatory that all tightenings are done with a torque wrench to the specifications set by the manufacturers and to apply anti-friction paste in contact areas such as the seat post or between the handlebars and stem.

When everything fails

If despite everything we cannot find the source of the noise, we will have no choice but to follow a trial and error method. Removing parts, cleaning them, lubricating them, and putting them back together. And so on until we find the source of the noise, which can sometimes come from such unsuspected places as a simple rubbing of the cleats with the pedals due to a bad pedaling gesture.

In the worst case, disassembling the bike, cleaning all its components thoroughly, and reassembling it as if it were new can end up being the last resort, although it is something complicated for most as it requires certain mechanical knowledge and having a series of specific tools that are not usually found in domestic workshops.